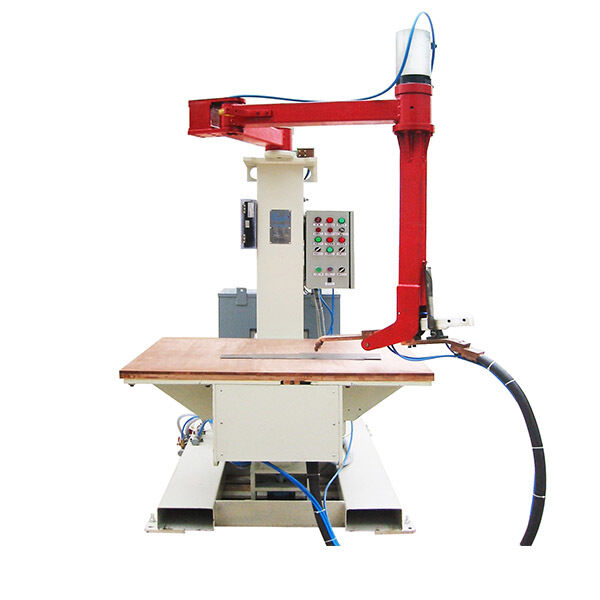

Table Spot Welding Machine: Eliminate Weld Imperfections in Precision Bending Tasks

The Sheet Metal Reinforcement Welding Machine is a high-performance industrial equipment designed for seamless welding of metal sheets (e.g., steel, aluminum, stainless steel) in structural reinforcement applications. Combining advanced arc welding technology with automated precision, it ensures robust joint strength, minimal deformation, and superior durability for heavy-duty fabrication.

Intelligent welding control system - Intelligent Touch Screen Controller for input and reading welding parameters. The welding conditions can be easily set using the touch panel system. You can save different welding parameters for different materials and thicknesses, allowing easy recall of welding programs.

Welding platform - Flat large copper table for welding various sheet metal door panels. If the workpiece can be placed on the table-type electrode, it can be welded without auxiliary personnel. The welding gun moves freely, allowing easy access to desired welding points by one person.

Standard Welding Electrode - Welding can be done efficiently by changing the electrode tip according to the type and size of product. It can also weld nuts, screws, and other fasteners.

Easy Setup and Operation - Comfortable working position: No need to hold the workpiece during welding; pressurization is automatic, greatly reducing the physical burden on the operator.

Designed specifically to address the critical challenges of weld quality in precision bending applications, our Table Spot Welding Machine redefines reliability and accuracy for metal fabrication professionals. Whether you're working on thin-gauge sheets, complex bent components, or high-precision parts for industries like automotive, electronics, or medical devices, this machine delivers consistent, flawless welds that eliminate common imperfections—such as spatter, uneven fusion, cold joints, or distortion—that often plague standard welding equipment in bending tasks.

Core Advantages for Precision Bending Scenarios

- Imperfection-Free Weld Formation: Equipped with advanced current control technology and high-precision electrode positioning system, ensuring uniform heat distribution across the weld spot. This minimizes thermal stress on bent workpieces, preventing warping or deformation while achieving full fusion between metal layers—critical for maintaining dimensional accuracy of pre-bent components.

- Adaptive Bending Compatibility: Compact tabletop design and adjustable clamping force accommodate various bent part geometries, from simple angles to complex 3D-formed structures. Flexible electrode arms reach tight spots on bent edges, ensuring secure welds even in hard-to-access areas.

- Consistency & Repeatability: Integrated digital control panel allows operators to store and recall custom welding parameters (current, pressure, weld time) for specific bending tasks, eliminating human error and ensuring every weld meets high standards.

- Damage Prevention for Thin Materials: Low-spatter welding process and soft-clamping mechanism protect workpiece surfaces from scratches or indentations, preserving both aesthetic and functional quality for thin-gauge metals.

Table Spot Welding Machine Features

- The movement patterns of crank arm mobile flat plate spot welder can be chosen as manual or CNC automatic mobile type.

- The structure of manual mobile method is simple, convenient, and flexible to move manually with simple locating of welding spots. Good applicability to complicated products.

- Automatic mobile method adopts coding servo motor, equipped with precision-machined slide rail, ball screw, and automatic testing system for complete electrode automatic movement.

- Automatic device utilizes X, Y axis mobile working table with PLC to store setting mobile programs for simple and convenient setup.

- Adopts direct single-point welding method with lower electrode designed as complete flat surface, suitable for welding flat plates with multiple welding spots while guaranteeing surface smoothness and welding spot consistency.

Specifications

| Model |

WL-SF-50/75/100K |

| Input Power (V/φ) |

380/3 |

| Rated Power (KVA) |

50/75/100 |

| Applicable Material |

Stainless Steel, Carbon steel, Aluminum, Metal |

| Electrode Force (KG) |

250-400 |

| Welding Thickness (MM) |

3.0+3.0 |

| Warranty |

1 year |

Application and Samples

We can provide customized service for you. Our engineers will discuss specific welding requirements with you and develop suitable technical proposals based on your samples or drawings.

Applicable industries: Various industries such as chassis and cabinets, elevators, electrical cabinets, automobiles, steel and wood furniture, kitchen appliances, etc.

Factory & Certificate

HWASHI: 22+ Years Experience Welding Solutions Expert

Guangdong Hwashi Technology Inc., established in 2001, is located in Huizhou, Guangdong province in China. We are a high-tech enterprise specializing in developing, manufacturing, and selling resistance welding machines, automatic welding machines, and industrial robot stations. We have two manufacturing plants covering approximately 60,000 square meters with about 200 staff members, including more than 20 mechanical and electrical engineers with over 10 years of experience in the welding industry.

We hold more than 70 patents for welding machine projects. Our machines have been exported to more than 70 countries worldwide, with local distributors in Russia, Turkey, Romania, Saudi Arabia, Malaysia, Indonesia, India, and USA, providing professional pre-sales and after-sales service locally.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!