Detailed Description

This machine is composed of main body, feeding system, welding and forming system, cutting system and control panel.

Through the feeding system-wire output wheel, the braid wire enters into the welding center to complete the process of feeding wire. Then the wire output system stop working, the welding forming device start working to press the wire on the preset position. The cylinder will press down to complete the welding. Next, the stay wire cylinder start to output the wire to preset length. When reaching the preset value, the cutting device starts cutting the wire. At last, the stay wire cylinder starts to pull out the completed wire and put it into the discharging box.

The welding length is 30-300mm (adjustable).

Technical Parameters

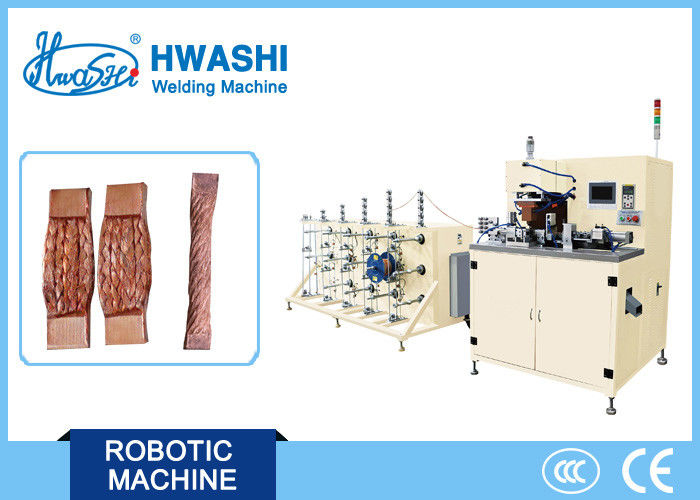

Copper Braided Wire Automatic Welding and Cutting Machine

Application

Welding of braid wire of electrical parts like distribution switch, disconnector, etc. Be able to weld and cut 1 to 25 mm2 of singlet wire, double wire, and three-wire in one of annealed copper wire.

The cutting length could be adjusted freely and the cross-section of connecting wire could be designed as different shapes like semi-circle, square, and hexagon, etc.

Material Configuration

1. Adopt silicon controlled from IXYS of United Stated with high precision and long service life.

2. Adopt integrated circuit from Motorola of U.S. and PLC from Japan SIEMENS with quick response and stable performance.

3. Adopt Japan Panasonic intelligent touch screen control system which is installed with automatic bug alarm system. Clear interface, easy operation, and stable performance.

4. Adopt self-developed intelligent microcomputer welding control system to control the compensation for the fluctuation of circuit built-in voltage in order to ensure the fluctuation of voltage is within ±15%. Prompt current compensation to ensure the stable welding current of power source.

5. Adopt South Korea SANWO pneumatic components with stable performance.

6. Adopt Taiwan TECO servo motor with powerful strength, high precision and stable control.

7. The transformer adopts Japan high purity silicon steel sheet with good magnetic and electricity conductivity. Less power consumption, more powerful and stable capacity.

8. Strictly comply with CE security standard to design the machine. Lower the accident rate.

Samples

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!