The medium frequency inverter spot welding machine can recity three-phase AC to DC and DC inverters into medium frequency 1000Hz square wave through the inverter circuit composed of IGBT. Then medium frequency 1000Hz square wave is connected into the primary of welding transformer, and the welding transformer make it with lower voltage and rectift it to be a dc supply electrode with little pulsation to the electrodes to weld the work piece, The inverter can adjust the duty ratio of IGBT by feedback the primary or secondary welding current, so as to achieve the effect of consulant current in the welding process.

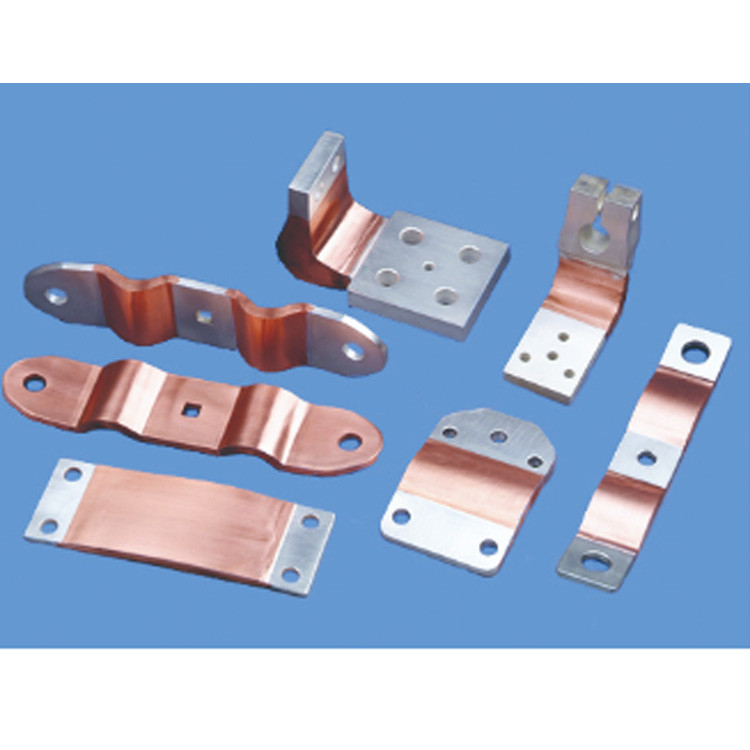

HWASHI 300KVA MF DC Flexible Copper Busbar Welding Machine is the special designed machine for welding flexible copper busbar.The size ranging from 50x50x5mm to 150x150x15mm (or customized according to your requirement)

Features of The Medium Frequency Inverter Spot Welding Machine

1. The current in secondary welding loop is DC, Dramatically reduce the impact to the welding current due to the inductive reactance in secondary loop when conducting welding to the work piece.

2. Three-phase balanced load can reduce the requirement to the power supply system. The power factor is close to 1. No electrical inductance so no need to adjust the power factor.

3. Eradicate the contamination to the power supply. It is a kind of environmentally friendly welding mode. No need to provide power independently. It is able to be used together with robot welding fixture system.

4. Reduce power consumption, save energy. Reduce the requirement of cables and lots of maintenance cost.

5. The weight of transformer is reduced greatly. It is light and convenient. The weight and size of the MF transformer is only 1/3 of the AC type transformer. Suitable for robot welding system.

6. Increase the heat input efficiency. The output of welding transformer is DC voltage, without the disturbance of inductance. Pure DC has no defect of zero passage. The efficiency of heat is enhanced dramatically.

7. Intelligent digital full-closed loop control. The welding control current will be more precise. The adjustment precision and monitoring precision is 20 times higher than the AC system. Be able to protect the inverter and transformer.

8. Increase the stability of the welding technology. DC welding technology is good and the welding parameters are of wide application. The secondary current could achieve actual constant current. Have better using prospect than AC.

9. Digital control can better improve the current control and measurement accuracy. The welding time precision is ms which can help you control the welding time at random.

10. Be able to weld aluminum and galvanized metal with good welding quality.

11. Especially suitable for welding three-layer metal sheet or very thin material and precision welding requirement.

12. Precision inverter DC resistance welding. Higher inverter frequency, more accurate control of the current.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!