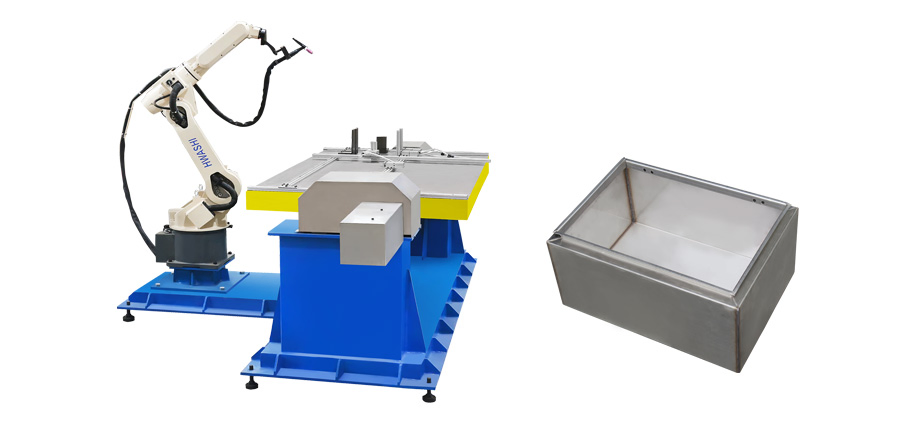

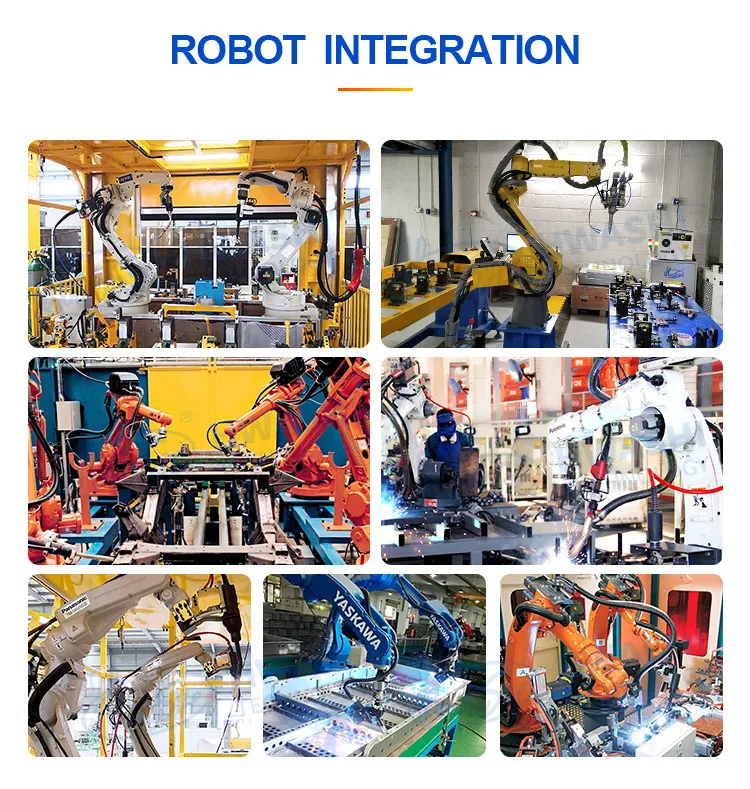

1.The complete welding robot system includes one set of HS-R6-08 1.4m arm length robot, 1 set of 400A TIG welding machine, 1 set of automatic anti-collision welding gun, 2 sets of one-axis vertical rotation positioner, and 2 sets of adjustable welding fixtures, etc. 2.Automatic welding is carried out by a six-axis robot MIG welder. The cylinders or fast clamps are used to fix the position of the product with the lever principle to ensure the positioning requirements of automatic welding of the robot, so as to ensure that it can be welded to each part of the product. According to the requirements of production efficiency, two sets of positioners are designed, one for loading and unloading of the workpiece, and the other for welding.

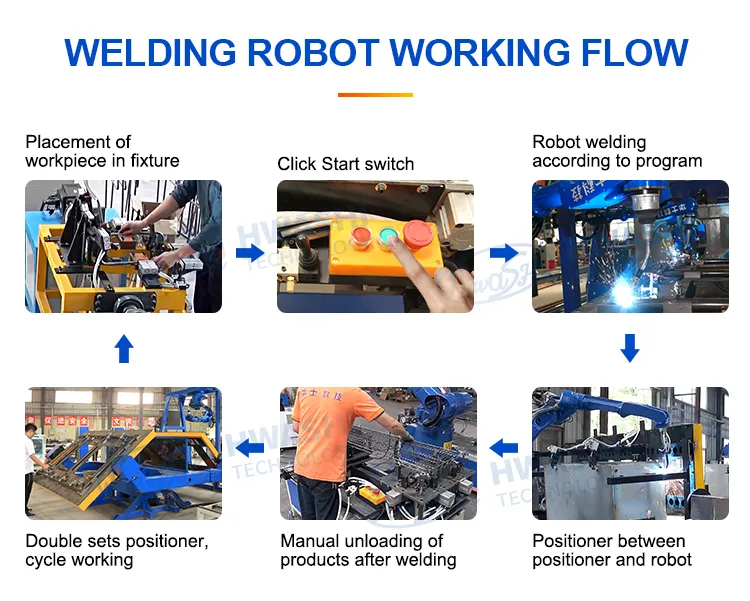

Workflow

1) Manual loading of the workpiece to the fixture in Station 1 fixed table;

2) Start welding;

3) The robot and welding machine will do welding on the workpiece according to the presetting program;

4) Welding completed;

5) While the station 1 is being welded, station 2 is being loaded and fixed the work piece synchronously. Two stations work alternately.

6) Cycle working

7) This machine can achieve automatic welding with manually loading material. It can also improve the welding quality and welding efficiency. What's more, it can reduce the production cost. The problem of unstable quality and low production efficiency caused by pure manual operation has been solved.

Machine list

1. Positioner, manual loading;

2. Cylinder for clamping the product;

3. Cylinder to turn over the fixture;

4. Robot automatic welding;

5. Manual unloading the product;

6. Welding gun cleaner device

Machine list

1. Positioner, manual loading;

2. Cylinder for clamping the product;

3. Cylinder to turn over the fixture;

4. Robot automatic welding;

5. Manual unloading the product;

6. Welding gun cleaner device