Hwashi CNC Auto Feeder Single Head Oven Racks Welding Machine, Wire Mesh/Kitchen Rack Automatic Wire Mesh Spot Welding Machine

Product Description

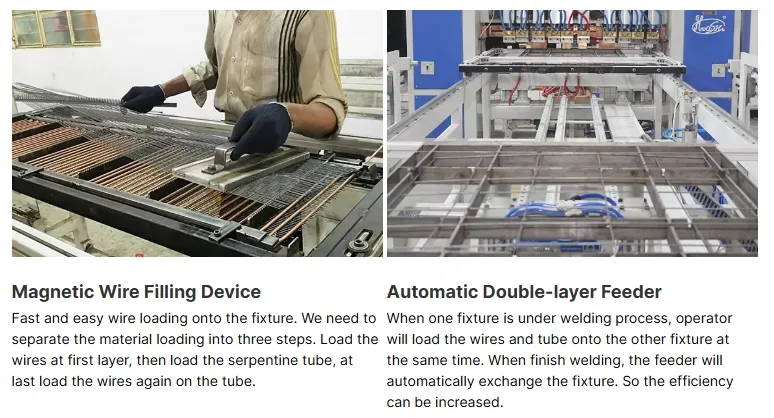

1.This machine is designed as single-electrode welding machine with long arm type X, Y axis automatic mobile feeding system. Only have to change the fixture could you use it to weld different shape of wire mesh.

2.You only have to input the data like the coordinate data of the welding samples, welding current, etc. then start the machine. It will conduct welding automatically. Worker only have to put the material onto certain position then take out the welded product.

3.The structure of the machine is simple, and the assembly is easy. Be able to match with different welding machines.

4. Adopt the servo motor to drive the X, Y axis to run in the PLC preset program. Max to store 5000 welding positions and 18 sets welding models (18 types of welding positions and welding current of wire mesh)

5. Especially suitable for welding iron wire mesh, door reinforcing rib, air conditioner backboard

6. It is equipped with low cost and low consumption AC power source with stable welding

7. X direction range: max 1000mm Y direction range: max 1000mm.

Features

The Welding spots are good in looking, firm, and stable and reliable. Well consistency of welding spots. Wide application. The machine, electricity and other mechanism could be reasonably assembled. It could be used to weld other similar products after relevant modification of microcomputer data program. One machine could serve several purposes. Design Working Life: 8-10 years

Functions Options Wide application. The machine, electricity and other mechanism could be reasonably assembled. It could be used to weld other similar products after relevant modification of microcomputer data program. One machine could serve several purposes.

|

Model

|

WL-TSP-100/150K

|

|

Input Power (V/φ)

|

380/3

|

|

Rated Power (KVA)

|

100/150

|

|

Applicable Material

|

Stainless Steel, Carbon steel, Aluminum, Metal

|

|

Electrode Force (KG)

|

250-400

|

|

Wleding Thickness (MM)

|

1-5mm

|

|

Warranty

|

1 years

|

|

Mesh Welding Range

|

1000mm X 1000mm

|

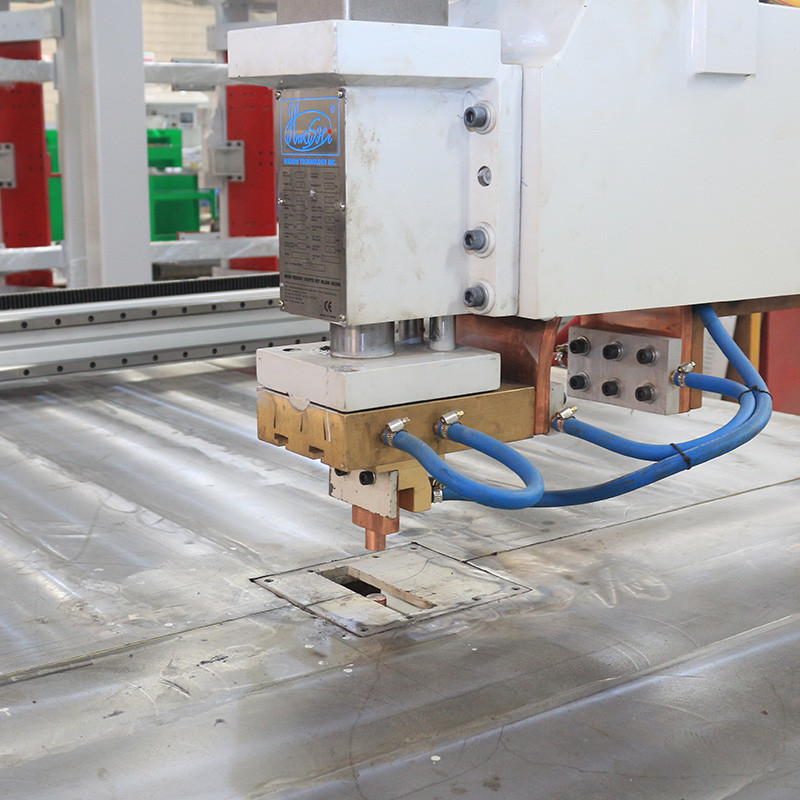

XY axis automatic moving wire welding machine

The XY axis mold frame is driven by servo motor with synchronous belt drive, and the walking step length and speed are controlled by the control system. When the manual material is fixed on the mold frame, the switch is activated and controlled by the industrial control computer, the product will walk alternately with the X and Y axes of the mold frame to automatically complete the welding of each part of the joints, and will automatically return to the origin when the welding is completed, without the need for manual operation by other personnel. At the same time, the operator can set up the material to prepare for the next welding work, which not only reduces the labor cost, but also effectively uses the welding time to set up the material.

Features:

- Product Name: Refrigerator Wire Tube Condenser Production Line Machine, Welding and Bending Machine

- Weight: 500-1000KG

- Welding Accuracy: High Accuracy

- Welding Speed: High Speed

- Wire Diameter: 0.2-2.5mm (According To Power)

Applications:

Wire Mesh Welding Equipment, such as the Hwashi WL-SQ-250K model, is a versatile and essential machine used in various industries for different applications. The product is manufactured in China and comes with CE certification, ensuring high quality and safety standards.

One of the key application occasions for this Mesh Welding Machine is in the production of wire mesh products used in construction, agriculture, fencing, and industrial settings. The machine's high accuracy welding capability makes it ideal for creating precise and durable wire mesh panels that meet specific size and shape requirements.

With a minimum order quantity of 1 and a price range between $20000-$50000, the Wire Mesh Welder is accessible to both small-scale and large-scale operations. The packaging details include a sturdy wooden box to ensure safe transportation, and the delivery time is estimated at 30-60 days, depending on the order size.

Customers can benefit from flexible payment terms such as T/T and L/C, making it convenient to acquire this essential equipment. The Supply Ability of 10 sets per month ensures that the demand for Wire Mesh Welding Equipment can be met promptly.

Operating on AC power supply, the machine offers both automatic and manual operation modes, providing users with flexibility based on their production needs. Weighing between 500-1000KG, the machine is relatively portable and can be easily moved within a workspace.

The high-speed welding capability of the Wire Mesh Welding Equipment enables efficient production processes, leading to increased productivity and output. Whether it's creating mesh panels for security fencing or industrial applications, this machine delivers consistent and reliable results with every use.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!