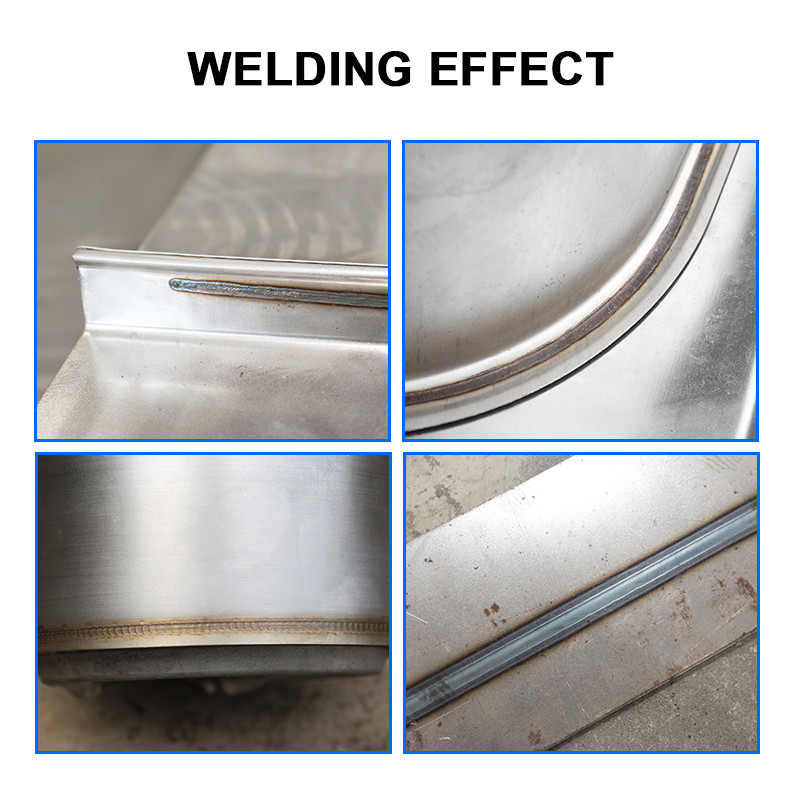

HWASHI Seam Welding Machine for Ventilation Duct Manual Tin Can Side Welder Roll to Roll Banner Welder 75KVA 26500A

The HWASHI Seam Welding Machine is a high - performance welding equipment engineered to meet the welding requirements of multiple applications, including ventilation ducts, manual tin cans, and roll - to - roll banners. With a power rating of 75KVA and a maximum welding current of 26500A, it delivers stable and efficient welding performance, ensuring strong and consistent weld seams across different workpieces.

SPECIFICATION

|

Model

|

WL-FS-AC75K

|

WL-FS-MF75K

|

WL-FS-MF100K

|

|

Input Voltage

|

Three-phase 380V±10% 50Hz

|

Three-phase 380V±10% 50Hz

|

|

Input Power

|

75KVA

|

100KVA

|

|

Rated Input Current

|

115A

|

150A

|

|

Rated Duty Cycle Rate

|

50%

|

50%

|

|

Max Secondary Floating Voltage

|

DC9.75V

|

DC11.6V

|

|

Secondary Max Short Circuit Current

|

26500A

|

28000A

|

|

Welding Transformer Insulation Grade

|

Grade F

|

Grade F

|

|

Program Segment Time Adjustment Range

|

0~9999SEC

|

0~9999SEC

|

|

Controller Heat Adjustment Range

|

15%~99%

|

15%~99%

|

|

Upper Welding Wheel Diameter

|

280mm

|

|

Lower Welding Wheel Diameter

|

40mm

|

|

Welding Wheel Width

|

3mm

|

|

Welding Wheel Rotating Speed

|

800-4000mm/min (adjustable)

|

|

Upper Welding Wheel Throat Depth Distance

|

400mm

|

|

Lower Welding Wheel Throat Depth Distance

|

400mm

|

|

Upper and Lower Welding Wheel Distance

|

50mm

|

|

Air Pressure

|

0.6MPa

|

|

Gas Consumption

|

10m3/h

|

|

Water Pressure

|

0.2Mpa

|

|

Water Temperature

|

10-20℃

|

|

Cooling Water Consumption

|

800L/H

|

DESCRIPTION

The Automatic Roll-Round Welding and Forming Equipment is an integrated advanced system designed to achieve automatic forming and welding operations on cylindrical workpieces. By combining roll-round forming and welding processes, this equipment significantly enhances production efficiency while ensuring high-quality finished products. 1. Automated Forming: The equipment features automatic roll-round forming capability, enabling precise and consistent forming of cylindrical workpieces, reducing manual labor and improving operational efficiency. 2. High-Precision Welding: Equipped with advanced high-precision welding technology, the equipment ensures accuracy and consistency during the welding process, guaranteeing the welding quality of the finished products. The Automatic Roll-Round Welding and Forming Equipment seamlessly integrates forming and welding processes, providing production lines with an efficient and precise solution. Its automation features and integrated design make it an ideal choice for achieving high output and top-quality finished products.

Woven Wire Mesh Filter Cartridge Applications

Woven wire mesh filter cartridge is widely used in petroleum, chemistry, metallurgy, machine, medicine, automobile industries for distillation, absorption, evaporation and filtration processes, so as to eliminate the impurities and foam mixed in the gas and liquid. 1.Filtration of air: air filters, vacuum filters, filtration of corrosive gases, etc. 2.Filtration of liquid: ceramics polluted water cleaning, beverage, disposal of sewage water, filtration of corrosive liquids, beer brewing filter, etc. 3.Filtration of solid: glass, coal, food processing industry, cosmetics, fluidised beds, etc. 4.Filtration of oil: oil refining, hydraulic oil, oilfield pipelines, etc. 5.Filtration of other fields: textile industry, insulation industry, automotive industry, chemical industry, metallurgy, medicine making, electronic field, etc.

FEATURE

- Ventilation Duct Welding: Specifically designed to weld ventilation ducts, it can handle the welding of duct seams with high precision. The machine ensures airtight and durable welds, which are crucial for the proper functioning of ventilation systems in commercial and industrial buildings.

- Manual Tin Can Side Welding: Ideal for the production of manual tin cans, it can precisely weld the side seams of tin cans. This ensures the structural integrity and airtightness of the cans, which is essential for preserving the contents, whether for food storage or other uses.

- Roll - to - Roll Banner Welding: Capable of welding roll - to - roll banners, it provides consistent and high - quality welds for banner seams. This helps in creating durable and long - lasting banners for advertising and promotional purposes.

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time delivery.

6. Prompt Response to Customers: Your satisfaction is the goal we pursue.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!