Product Description:

XY axis wire welding machine High Speed Full Automatic Security Fence Panel Wire Mesh Welder Welding Machine

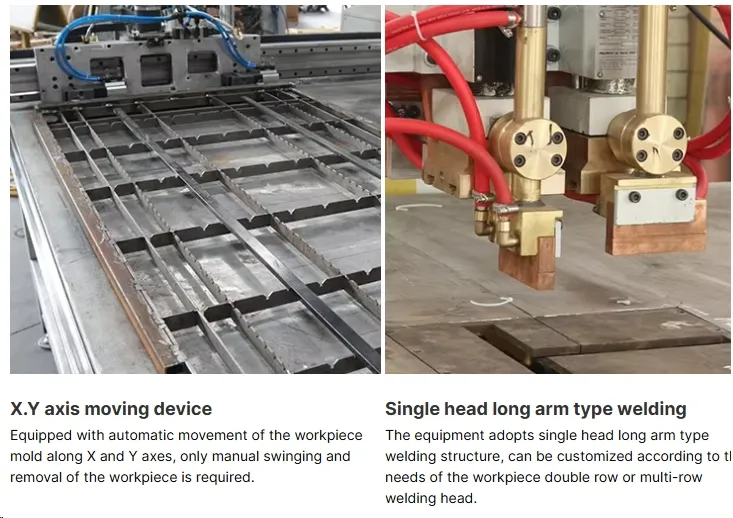

wire welding machine adopts a single-head long arm type welding structure, equipped withwork piece molds that move along the X and Y axis automatically. Input coordinatedata ofwelding position, welding current and other data to realize autormatic welding.Just need to load the material manually and take out the work piece. lt is suitable for the welding ofthe mesh with in the range of 1000mm X 1000mm.

Specification

| Model |

WL-TSP-100/150K |

| Input Power (V/φ) |

380/3 |

| Rated Power (KVA) |

100/150 |

| Applicable Material |

Stainless Steel, Carbon steel, Aluminum, Metal |

| Electrode Force (KG) |

250-400 |

| Wleding Thickness (MM) |

1-5mm |

| Warranty |

1 years |

| Mesh Welding Range |

1000mm X 1000mm |

XY axis automatic moving wire welding machine

The XY axis mold frame is driven by servo motor with synchronous belt drive, and the walking step length and speed are controlled by the control system. When the manual material is fixed on the mold frame, the switch is activated and controlled by the industrial control computer, the product will walk alternately with the X and Y axes of the mold frame to automatically complete the welding of each part of the joints, and will automatically return to the origin when the welding is completed, without the need for manual operation by other personnel. At the same time, the operator can set up the material to prepare for the next welding work, which not only reduces the labor cost, but also effectively uses the welding time to set up the material.

The Hwashi Automatic Multiple Welded Wire Mesh Spot Welding Machine comes with several options to choose from, including a power supply, feeder, unloading device, automatic bending device, and an automatic straightening and cutting machine. These features make this wire mesh welder a versatile tool that can be used for a range of applications and welding needs.

One of the standout features of the Hwashi Automatic Multiple Welded Wire Mesh Spot Welding Machine is its dimension flexibility. According to your product, you can customize the dimensions of this wire mesh welder to meet your specific welding needs. This feature ensures that you get a machine that is perfectly tailored to your unique requirements.

The Hwashi Automatic Multiple Welded Wire Mesh Spot Welding Machine has an effective welding width of 1200mm, which makes it ideal for welding large wire mesh products. This feature ensures that you can complete your welding projects quickly and efficiently, without compromising on the quality of your work.

The Hwashi Automatic Multiple Welded Wire Mesh Spot Welding Machine also comes equipped with an automatic double-layer feeder. This feeder is designed to load wires onto the other fixture while one fixture is under welding process. This feature ensures that you can maximize your productivity and efficiency by reducing the time it takes to load wires onto the machine.

In conclusion, if you are looking for a high-quality wire mesh welder that can deliver precise and efficient welding results, the Hwashi Automatic Multiple Welded Wire Mesh Spot Welding Machine is the perfect choice for you. With its advanced features and functionality, this wire mesh welder is a must-have for any business that wants to improve its welding capabilities and take its welding capabilities to the next level.

Features:

- Product Name: Wire Mesh Welding Machine

- Warranty: 1 Year

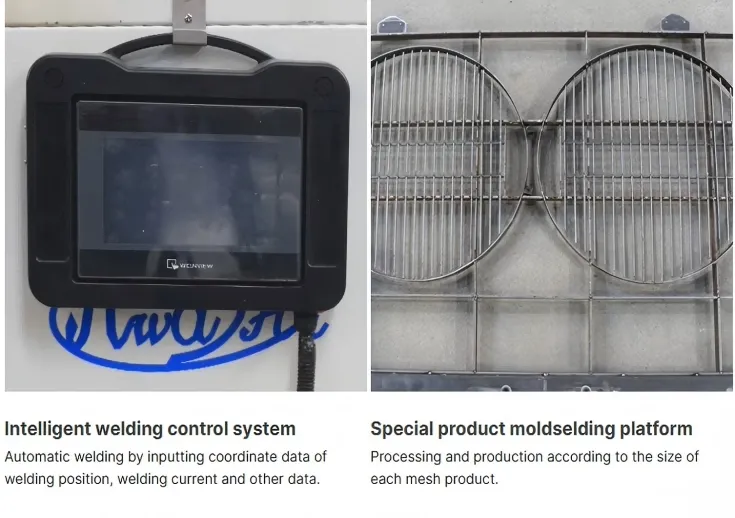

- Intelligent welding control system: Automatic welding by inputting coordinate data of welding position, welding current and other data

- Core Components: PLC, Engine, Motor

- Wire Frame Bending Machine: Bends flat or round wires into square shape wire frame

- Welding power source: Three-phase MF DC power supply system OR two-phase AC power supply system

- Keywords: Wire Mesh Welder, Steel Mesh Welding Equipment, Steel Mesh Welding Equipment

Technical Parameters:

|

Product Name:

|

Wire Mesh Welding Machine

|

|

Dimension(L*W*H):

|

According To Your Product

|

|

Welding power source:

|

Three-phase MF DC power supply system OR two-phase AC power supply system

|

|

High Speed Wire Straightening and Cutting Machine:

|

Makes batch production of 2mm to 4mm wires at almost 5 times the normal speed

|

|

Welding Power Source:

|

AC / MF DC

|

|

2D Wire Handle Bending Machine:

|

Bends wire handle for 2-6mm wire bending

|

|

Warranty:

|

1 Year

|

|

Welding Heads and Fixtures:

|

Processing and design according to the drawings of each wire shelf product

|

|

Automatic Wire Filling System:

|

Automatically fills the fixture with precut straight wires

|

|

Weight:

|

According To Your Product

|

|

Wire Frame Double T-Butt Machine:

|

Welds the cross bars of the wire shelf to the wire frame with double head design

|

Applications:

The HWASHI wire mesh welding machine is suitable for different welding applications, such as the manufacturing of wire mesh fences, wire mesh cages, wire mesh grids, and wire mesh shelves. This machine is perfect for businesses that require a high degree of customization, as it can be programmed to weld various wire diameters and mesh sizes. The machine's effective welding length is 3000mm, and the effective welding width is 1200mm, making it highly efficient and suitable for large-scale production.

The WL-TP-150K model is equipped with core components such as a PLC, engine, and motor, ensuring that the machine operates smoothly and efficiently. The machine's full-automatic stainless steel mesh welding capabilities make it an excellent choice for businesses that require highly accurate and consistent welds. The machine's multiple welding heads allow for simultaneous welding, further increasing production efficiency.

The HWASHI wire mesh welding machine is designed to be user-friendly, making it easy to operate and maintain. The machine's delivery time is 7-30 working days after receiving payment, and it is packaged in a sea-worthy wooden package to ensure safe transport. The machine's supply ability is 50 sets per month, and its price is negotiable. Payment terms are L/C and T/T.

The HWASHI wire mesh welding machine is an ideal solution for businesses looking for a reliable and efficient wire mesh welder. Its welded mesh making machine capabilities make it highly versatile and suitable for various wire mesh welding applications. Whether you are in the manufacturing industry or the construction industry, the HWASHI wire mesh welding machine is an excellent investment that will help streamline your production process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!