Advanced Wire Mesh Welding Machine for Shopping Cart Manufacturers Hwashi s Adaptive Technology Ensures Consistent

Hwashi Automatic Multiple Head Wire Mesh Spot Welding Machine is a game-changing solution for shopping cart manufacturers, engineered to solve core pain points in wire mesh component welding—from inconsistent quality to low production efficiency—via its proprietary Adaptive Welding Technology.

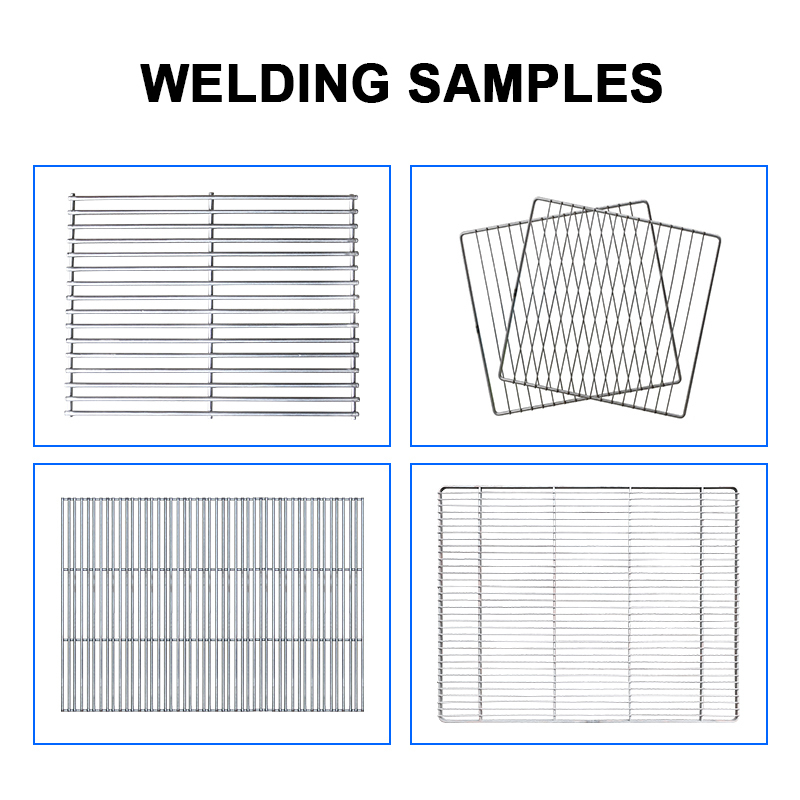

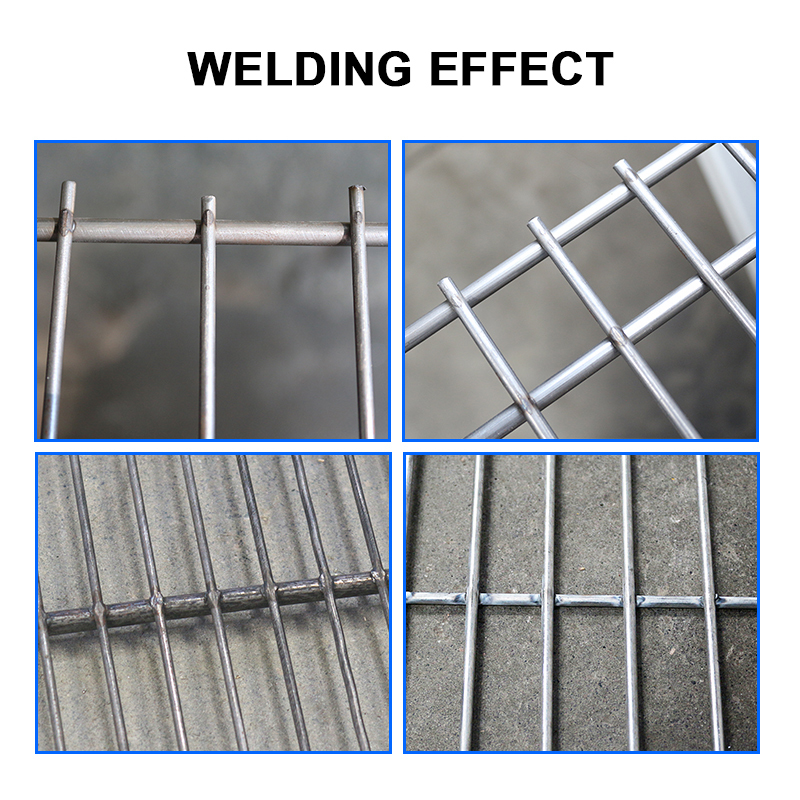

Designed specifically for shopping cart wire mesh (e.g., basket grids, frame supports), the machine’s Adaptive Welding Technology acts as a “smart adjuster”: it automatically detects wire diameter (2-6mm) and material type (mild steel, stainless steel), then optimizes welding current (5-20kA) and pressure (0.2-0.8MPa) in 0.1-second increments. This ensures every weld spot meets load-bearing standards (withstanding ≥50kg pull force) and avoids defects like spatter or weak joints, directly enhancing shopping carts’ service life.

The multiple-head configuration (4/6/8 heads optional) is a productivity driver: it targets multiple welding nodes on shopping cart wire mesh simultaneously, cutting down the per-unit processing time by over half. For example, a standard supermarket cart’s wire mesh basket—once taking 6 minutes to weld manually—can now be finished in just 90 seconds. This high throughput makes the machine ideal for mass production lines with daily output demands of 500+ carts.

Flexibility is another key strength: the machine’s quick-change clamping system allows switching between different shopping cart designs (foldable, nested, child-seat equipped) in 20 minutes or less. Its high-precision linear guide rails (±0.1mm positioning accuracy) ensure consistent welding positions even after thousands of cycles, reducing rework rates to below 1%.

For long-term reliability, the machine is built with industrial-grade components: a heat-resistant welding arm (operating temp up to 80℃) and water-cooled system prevent overheating during 24/7 operation, while the PLC control system stores 100+ welding programs for easy recall. The 7-inch touchscreen HMI simplifies operation—even new operators can master basic functions in 1 day.

Hwashi also provides end-to-end support: free on-site installation, 3 days of operator training, and 18-month warranty (extensible to 24 months). With this machine, shopping cart manufacturers can not only cut labor costs by 40% but also elevate product quality to meet global market standards.

Introducing Hwashi’s state-of-the-art Automatic Wire Machine, a brand-new, fully automated production line engineered to revolutionize wire mesh deck shelving manufacturing. Designed for precision, speed, and reliability, this cutting-edge system redefines efficiency in creating high-quality wire mesh decking—perfect for warehouses, retail storage, and industrial shelving solutions.

Crafted to deliver peak performance from day one, the production line arrives in pristine, new condition, with every component calibrated to meet strict quality standards. Whether you’re scaling up production or launching a new shelving line, this system eliminates the hassle of outdated machinery, ensuring consistent output from the first run.

At the core of its appeal is full automation, streamlining every step from wire feeding and mesh welding to cutting and forming. The integrated control panel lets operators program custom dimensions—adjusting mesh size, deck thickness, and panel length with pinpoint accuracy—reducing human error and minimizing material waste. What once took hours of manual labor now happens in minutes: the line can produce up to [X] wire mesh deck panels per hour, slashing lead times and boosting your production capacity.

Durability is built into every weld. The machine uses advanced high-frequency welding technology to create strong, uniform joints, ensuring each wire mesh deck can withstand heavy loads (up to [X] kg per panel) without sagging or warping. This makes it ideal for heavy-duty storage environments where safety and longevity are non-negotiable.

|

|

|

Intelligent welding control system

Automatic welding by inputting coordinate data of welding position, welding current and other data

|

Welding Heads and Fixtures

Processing and design according to the drawings of each wire shelf product. (customized

|

|

|

|

Automatic Wire Filling System

You can put the precut straight wires into the hopper, then the wire filling machine will do the wire filling into the fixture automatically. It helps to increase the working efficiency and reduce labor force

|

Automatic Double-layer Feeder

When one fixture is under welding process, the wire filling system will load the wires onto the other fixture at the same time. When finish welding, the feeder will automatically exchange the fixture. So the efficiency can be increased.

|

Production Line Machines

|

|

|

Wire Flattening and Cutting Machine

This machine is able to process the round wire into flat wire. It will automatically feed the round wire and cut it into required length.

Normally you will need to prepare the 8mm wire coil, and make it into 12x3mm flat wire strip.

|

High Speed Wire Straightening and Cutting Machine

This machine will help to make batch production of 2mm to 4mm wires. This machine speed is almost 5 times than the normal speed wire cutting machine. It helps to increase production rate and reduce labor cost.

|

|

|

|

Wire Frame Bending Machine

This machine helps to bend the flat or round wires into square shape wire frame. It is able to bend multiple wires at the same time so as to increase production rate.

|

Wire Frame Butt Welding Machine

The number of welding heads is depends on the welding width of the mesh. Different welding head can be set different welding programs and current respectively.

|

|

|

|

Wire Frame Double T-Butt Machine

This machine is used to weld the cross bars of the wire shelf to the wire frame. The double head design helps to increase the production rate. Easy Operation. We can also design the automatic moving and welding application.

|

Wire Edge Trimming Machine

After Welding, we need the trimming machine to cut off the edge of wire from the wire frame. To make the surface clean and smooth.

|

|

|

|

2D Wire Handle Bending Machine

This machine is used to bend the wire handle. It is suitable for 2-6mm wire bending. And you can bend any shape of the wire without changing mould.

|

3D Wire Bending Machine

This machine is used to bend the wire into 3D shape. It is suitable for 2-6mm or 3-8mm wire bending. And you can bend any 3D shape of the wire without changing mould.

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!