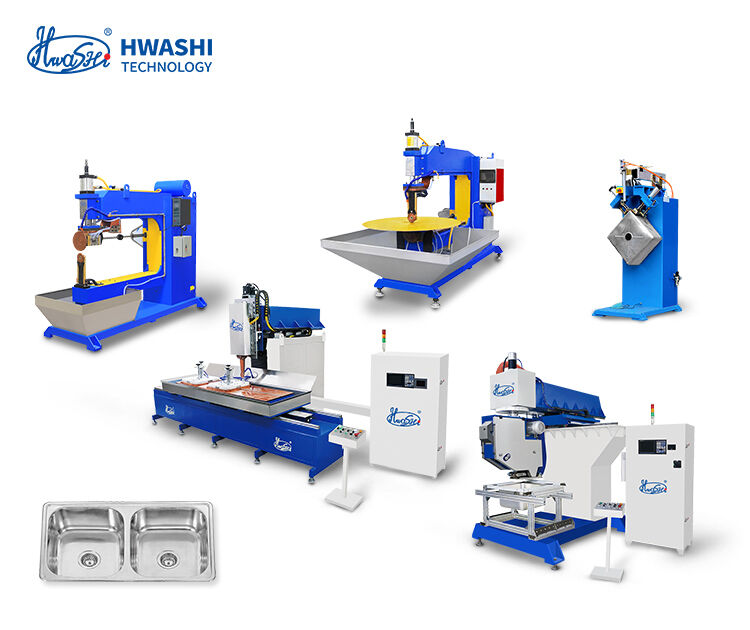

Hwashi Sink Welder: High-Strength Joints for Kitchen Utensil Manufacturing

The Hwashi Stainless Steel Kitchen Utensil Sink Bowl Seam Welding Machine is a specialized automated solution engineered to deliver flawless, high-strength seams for stainless steel sink bowls—critical components in kitchen utensil manufacturing.

Application

Designed to address the unique challenges of welding thin-gauge stainless steel (0.8-2mm thickness), this machine combines precision engineering with intelligent control to redefine seam quality and production efficiency. At its core is the advanced seam welding technology, which utilizes high-frequency resistance welding (HFW) paired with a servo-driven welding wheel system. This ensures uniform heat distribution along the sink bowl's curved or straight seams, creating airtight, leakproof joints with a smooth, post-weld surface finish (Ra ≤ 0.8μm)—eliminating the need for time-consuming manual grinding or polishing.

The machine's adaptive current control adjusts welding parameters in real time based on material variations (304/316 stainless steel) and seam length, guaranteeing consistent weld strength (shear strength ≥ 300MPa) that meets food-grade safety standards (FDA, LFGB). Tailored for sink bowl geometries, the machine features a customizable clamping fixture with 360° rotational capability, accommodating various sink designs—from single-bowl to double-bowl configurations, deep or shallow profiles, and even sinks with integrated drain grooves. The fixture's precision positioning (±0.05mm repeatability) ensures seamless alignment of sink components before welding, minimizing gaps that could lead to weak points or leakage.

Specifications

| Model |

WL-FS-AC75K |

WL-FS-MF75K |

WL-FS-MF100K |

| Input Voltage |

Three-phase 380V±10% 50Hz |

Three-phase 380V±10% 50Hz |

|

| Input Power |

75KVA |

100KVA |

|

| Rated Input Current |

115A |

150A |

|

| Rated Duty Cycle Rate |

50% |

50% |

|

| Max Secondary Floating Voltage |

DC9.75V |

DC11.6V |

|

| Secondary Max Short Circuit Current |

26500A |

28000A |

|

| Welding Transformer Insulation Grade |

Grade F |

Grade F |

|

| Program Segment Time Adjustment Range |

0~9999SEC |

0~9999SEC |

|

| Controller Heat Adjustment Range |

15%~99% |

15%~99% |

|

| Upper Welding Wheel Diameter |

280mm |

| Lower Welding Wheel Diameter |

40mm |

| Welding Wheel Width |

3mm |

| Welding Wheel Rotating Speed |

800-4000mm/min (adjustable) |

| Upper Welding Wheel Throat Depth Distance |

400mm |

| Lower Welding Wheel Throat Depth Distance |

400mm |

| Upper and Lower Welding Wheel Distance |

50mm |

| Air Pressure |

0.6MPa |

| Gas Consumption |

10m³/h |

| Water Pressure |

0.2Mpa |

| Water Temperature |

10-20℃ |

| Cooling Water Consumption |

800L/H |

Product Overview

The Hwashi Sink Welding Machine is a game-changer for kitchen utensil manufacturers seeking uncompromising joint strength and production reliability. Tailored specifically for sink fabrication and kitchenware production, this industrial-grade welding solution delivers consistent, heavy-duty welds that withstand the daily rigors of kitchen use—from frequent water exposure to mechanical impact.

Engineered with precision at its core, the machine integrates advanced welding technology to ensure uniform joint quality across every project. It excels with food-grade materials like stainless steel and durable alloys, creating bonds that resist corrosion, warping, and wear over time. Whether you're producing residential sinks, commercial cookware, or food preparation tools, this machine maintains exceptional performance to meet industry-leading standards.

Designed for efficiency, the Hwashi Sink Welding Machine streamlines production workflows. It minimizes defects, reduces rework, and adapts seamlessly to both small-batch workshops and large-scale manufacturing lines. Its user-friendly operation and robust build guarantee long-term productivity, making it a versatile asset for businesses aiming to elevate product durability and customer satisfaction.

Key Features

- Intelligent microcomputer single piece controller with pure digital setting, online computer programming, LED digital display, stable performance, and convenient online program modification

- Automatic welding current compensation during voltage fluctuations to ensure welding stability

- Digital circuit control with components from world-renowned manufacturers for long-term operational stability

- High-precision silicon controlled rectifiers from West Germany, IXYS and IR (USA) for stable current magnitude control

- Advanced mercury conductive technology for transmission tile axis with excellent performance in transmission and conductivity

- Welding roll wheel made from Japanese alloy copper material with high rigidity and good conductivity

- Transformer utilizing high-purity Japanese silicon steel sheets for superior magnetic and electrical conductivity, low power consumption, and stable power output

- Mosaic connection design for welding mold and machine assembly, facilitating easy assembly and disassembly

- Available welding power sources: AC pulse, secondary rectifying, and three-phase medium frequency types

Welding Technology

Seam welding is a form of permanent metal welding. When welding, welding pressure between two welding wheels spins the welding wheel, driving the weldment and electricity. The welding current creates local heating, forming successively overlapping joints to create continuous welds and achieve permanent bonding. Applications include casings (automobile, motorcycle fuel tanks), barrels (cans), and sheet-formed artifacts (wheels, mufflers, radiators).

The machine adopts 75KVA/100K medium frequency inverter DC power source with a 50% duty cycle rate while welding output current is 26KA. The three-phase power supply, through rectification by a special inverter, is converted into 1000Hz AC voltage and then transmitted to a medium frequency transformer where the current is rectified to supply DC welding current.

Competitive Advantages

- HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale with competitive pricing

- Customized Service: Design and development of welding machines according to your specific requirements

- Genuine Product with Excellent Quality: 12-month warranty, ISO9001:2000 and China Compulsory Certification compliance, 8-10 year service life, 100% pre-delivery testing

- After Sales Service and Technical Assistance: 24-hour technical support via email with professional team consultation

- Quick Delivery: Just-in-time delivery service

- Prompt Response to Customers: Dedicated to customer satisfaction

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!