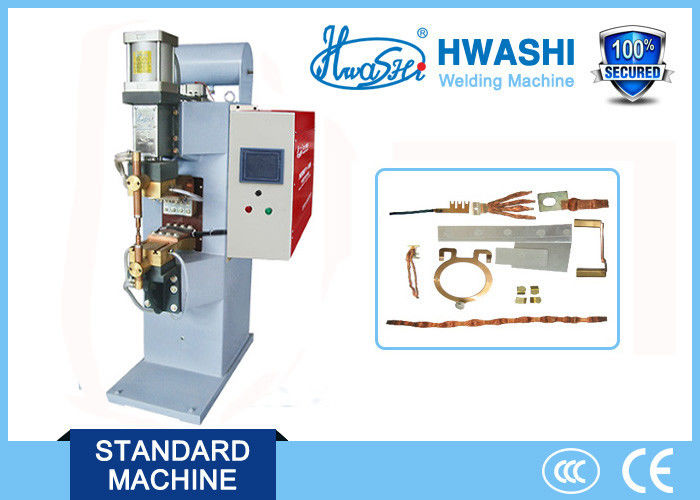

Three-phase MF DC Inverter Welding Machine

SPECIFICATION

|

Parameter/Model

|

MF-50K

|

MF-90K

|

MF-150K

|

MF-170K

|

MF-250K

|

MF-300K

|

|

Rated Voltage

|

3 phases,(AC), 380 or 415 or 480V, 50/60HZ.

|

|

Rated Capacity

|

50KVA

|

90KVA

|

150KVA

|

170KVA

|

250KVA

|

300KVA

|

|

Rated Duty Cycle

|

50%

|

50%

|

50%

|

50%

|

50%

|

50%

|

|

Max Welding Current

|

18000A

|

25000A

|

32000A

|

40000A

|

60000A

|

80000A

|

|

Electrode Stroke

|

60MM

|

|

Welding Arm Spacing

|

380MM

|

|

Air Source Pressure

|

0.6MPa

|

|

Cooling Water Flow

|

16L/Minute

|

25L/Minute

|

35 L/Minute

|

45L/Minute

|

APPLICATION

It is widely used in welding all kinds of metal, especially suitable for welding copper and aluminum etc.

DESCRIPTION

1.High quality,high efficiency.98% power factor,three-phase input load balancing,the impact on the

user grid has been greatly reduced, DC input current, smooth,inductance is zero. 1000HZ working frequency, time control precision is 1MS;

2.High strength body structure, good rigidity, direct pressurizing mechanism, linear bearings used in the guiding structure enable good mobility;

3.Adopt high-speed microprocessors,use intelligent optimal calculation method, LCD interface,can save 101sets welding schedule numbers. There are functions of switch display in both Chinese and English,provide external BCD call interface,system fault diagnosis alarm automatically.etc;

4.Specially suitable for welding higher conductive rate of material (such as aluminum,copper,silver and so on) and much more thicker workpiece,widely used in automobile,aerospace and other high request

products and industry.

FEATURE

1.Energy Saving: Compared with using AC power, it can help to reduce the consumption of electric energy. The same weight of transformer could output more energy. It can also be conveniently used with the large automatic welding clamp.

2. Reduce operation cost, including saving the energy of each spot welding and reducing the cycle of welding.

3. In a semi-automatic machine, one medium frequency transformer can replace many low frequency transformers which can help to reduce the parallel connection in secondary circuit.

4. Improve the power factor, reduce the production cost.

5. Reduce interference in secondary circuit which is in the large open area: the welding current is direct current. When there is induction or magnetic material in secondary winding, the welding will not be affected.

6. To make the power supply unit load balance: MF inverter spot/projection welder adopts the three-phase sources which can store energy.

7. More adaptable to the fluctuation of power grid and voltage drop: a part of the energy has been stored by inverter and been supplied to load. It replaces the way of power supply to load directly from the power grid.

8. More precise and fast control of current: Compare with low frequency system, it is able to analyze more parameters in a more precise way.

9. More reliable process: For most of the applied resistance welding metals, to use DC to weld will help to achieve better effect.

10. The technology of MF system is more traditional and reliable which can prevent the damage results from the breakdown of silicon controlled.

11. Reduce operation cost, including saving the energy of each spot welding and reducing the cycle of welding.

COMPETITIVE ADVANTAGE

1. Our dedicated Technical Service Staff is ready to assist in maintaining your Resistance welding equipment in top operating condition. We can also update and Retrofit older Resistance welders with current state of the art microprocessor based weld controls.

2. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

3. Prompt Response to Customers: Your satisfaction is the goal we pursue.

4. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

5. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

6. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

7. Quick Delivery: Our company provides just-in-time delivery.

8. Prompt Response to Customers: Your satisfaction is the goal we pursue.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!