Hwashi double station double welding head improve work efficiency spot welder

Hwashi double station double welding head spot welder is an advanced welding equipment designed to enhance work efficiency and welding quality. Here is its product description and key features:

Product Description:

Hwashi double station double welding head spot welder is an automated welding system aimed at providing efficient welding solutions for the manufacturing industry. It consists of two welding workstations, each equipped with dual welding heads, capable of simultaneously performing two welding tasks. This equipment is typically used in applications that require high throughput and consistency in welding, such as automotive manufacturing, metal fabrication, and electronics production, among others.

Key Features:

High Work Efficiency: The double station double welding head allows for two welding tasks to be carried out simultaneously, significantly boosting work efficiency. This means that more workpieces can be welded in a shorter amount of time.

Consistent Welding Quality: Due to automation control and precision welding head design, Hwashi double station double welding head ensures consistency and quality in every welding point, reducing the risk of welding defects.

Versatility: This equipment often offers various welding modes and setup options to accommodate different welding requirements. Operators can make adjustments and configurations based on specific tasks.

Intelligent Control: Hwashi welding equipment typically comes with advanced PLC (Programmable Logic Controller) and touchscreen interfaces, making operations more intelligent and user-friendly. Operators can easily set welding parameters and monitor equipment performance.

Safety and Reliability: Safety is a critical consideration for welding equipment, and Hwashi devices usually feature multiple safety functions to ensure the well-being of operators and the equipment.

Energy Efficiency and Environmental Responsibility: These devices often incorporate advanced energy management technologies to reduce energy consumption and minimize environmental impact.

Easy Maintenance: Hwashi double station double welding head is typically designed for easy maintenance, minimizing downtime and extending equipment lifespan.

In summary, Hwashi double station double welding head is a highly automated welding solution that can significantly enhance the efficiency and quality of welding operations while reducing labor input and the risk of welding defects. This makes it a valuable tool in the manufacturing industry, especially for applications that require high throughput and consistency.

|

|

|

Intelligent welding control system

Intelligent Touch Screen Controller Input and read

welding parameters, Optional Digital Dial Code Type, Intelligent Microcomputer Type, Touch Screen Type.

|

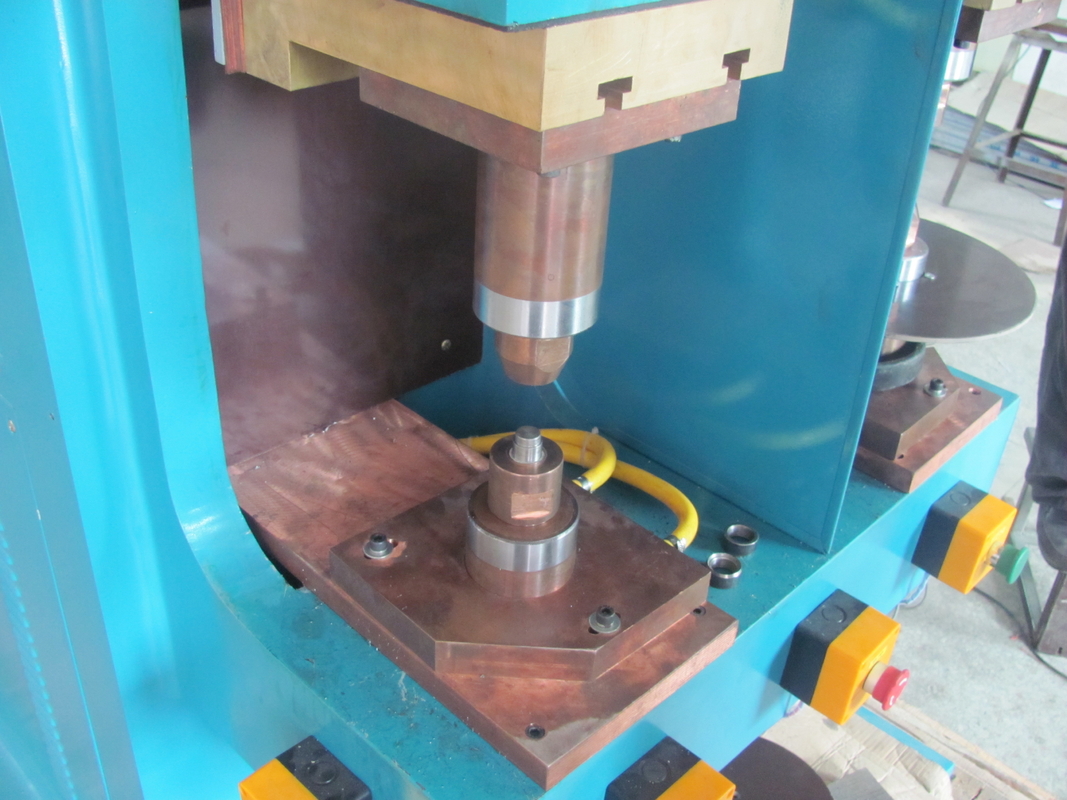

Raw materials made to standard

Thicker Copper Plate or Copper Belt To ensure stable conductivity in welding.

|

|

|

|

Custom processing of electrodes

Customized Electrodes which will be suitable for

Welding material like steel, aluminium, silver, stainless

Steel, and nickel steel. |

Shape structure and welding method

Design the right machine shape and mold according to

the welding product.

|

Features of The Capacitor Discharge Spot Welding Machine

1.The requirements for the power grid are low and do not affect the power grid.

2.The welding process is short, the instantaneous current is high, and the heat affected zone is small.

3.The water cooling circulation system helps to effectively reduce the consumption of electrodes and transformers.

4.The welding surface oxidation and deformation is small, no black coating, and no grinding process is required after welding.

Specification

|

Model

|

Voltage

V

|

Power

KVA

|

Output Head

W.S

|

Capacitance

UF

|

Electrode Force

KG

|

Electrode Stroke

MM

|

Overall Dimension

MM

|

| WL-C-1K |

220V 1PH |

1KVA |

300 |

3000 |

30 |

25 |

545 |

| WL-C-2K |

220V 1PH |

2KVA |

500 |

4500 |

100 |

50 |

545 |

| WL-C-2.5K |

220V 1PH |

2.5KVA |

1000 |

9000 |

100 |

50 |

545 |

| WL-C-3K |

380V 3PH |

3KVA |

1500 |

14000 |

350 |

80 |

950 |

| WL-C-5K |

380V 3PH |

5KVA |

3000 |

28000 |

350 |

80 |

700 |

| WL-C-7K |

380V 3PH |

7KVA |

4500 |

42000 |

800 |

100 |

950 |

| WL-C-10K |

380V 3PH |

10KVA |

6000 |

60000 |

1000 |

100 |

950 |

| WL-C-12K |

380V 3PH |

12KVA |

7000 |

70000 |

1000 |

100 |

950 |

| WL-C-15K |

380V 3PH |

15KVA |

8000 |

80000 |

1000 |

100 |

950 |

| WL-C-18K |

380V 3PH |

18KVA |

10000 |

15000 |

1000 |

100 |

950 |

| WL-C-20K |

380V 3PH |

20KVA |

15000 |

150000 |

1500 |

100 |

950 |

| WL-C-25K |

380V 3PH |

25KVA |

18000 |

18000 |

2000 |

100 |

950 |

| WL-C-30K |

380V 3PH |

30KVA |

20000 |

20000 |

2000 |

100 |

1100 |

| WL-C-40K |

380V 3PH |

40KVA |

25000 |

25000 |

2000 |

100 |

1100 |

| WL-C-50K |

380V 3PH |

50KVA |

30000 |

30000 |

2000 |

100 |

1100 |

| WL-C-60K |

380V 3PH |

60KVA |

35000 |

35000 |

2000 |

100 |

1100 |

Application and samples

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!