CNC Seam Welding Machine for Welding Square Pipe Frame and Mesh of Door Part ,Side Part and Back Pack

This CNC seam welding special machine utilizes the seam welding principle to replace the spot welding electrode with circle welding wheel. When the welding wheel rolls continuously or intermittently under continuous or intermittent current pulse, the welding seam which is composed of a series of welding spots will be formed. However, the distance between welding spots will be reduced which will make the nugget overlap with each other. When the overlap degree exceed 1/3 of the diameter of the nugget, then a certain degree of air tightness welding will occur. For the sake of ensuring the stability of welding quality, medium frequency inverter power source will be adopted. Adopt the professional automatic control system from Japan Mitsubishi, as long as inputting the data like coordinate data of the position of welding products, welding current, etc., then after turning on the machine, the welding track will automatically finish welding product within the preset procedure. The workers only need to put the work piece onto certain place and then take it away when finishing welding.

Adopt medium frequency inverter power source of welding and large flat platform of locating pattern. Use the servo motor to drive axle X (locating mould) and axle Y (welding electrode) to operate under the preset procedure of PLC data. It could store 15 sets of welding models at most (be able to store 15 sets of welding position and welding current of product). According to the stored position of welding spot, the welding product will be located inside the mould and moves horizontally along the X direction and the moving area should be no more than 1300mm. The welding electrode will be designed to move vertically along the Y direction and the moving area should be no more than 762mm. The welding electrode moves from top to bottom within 250mm along the axle Z direction and be able to conduct 360° of rotation under the control of servo motor so it is suitable for welding different angles of products.

Suitable for welding racks within the length 1630mm , width762mm

| Model |

WL-CNC-MF 120K |

| Input Power |

Three-phase 380V±10% 50Hz |

| Rated Capacity |

120KVA |

| Rated Duty Cycle |

25% |

| Maximum Secondary Floating Voltage |

12.5VAC |

| Maximum Secondary Circuit Current |

38000A |

| Insulation Grade Of Welding Transformer |

Grade F |

| Time Adjustment Range Of Program Segment |

0~9999ms |

| Heat Adjustment Range |

15%~99% |

| Control Program |

Pressurize, increase by degree, preheat, interval, welding, interval, tempering, sustain, stop, welding pulse count. |

| Power Grid Voltage Fluctuation Compensation |

When the voltage fluctuates between±10%, the secondary voltage fluctuates between≤ ±3% |

| Welding Wheel Diameter |

100-120mm |

| Welding Wheel Width |

3-5mm |

| Welding Wheel Speed |

1800-4000mm/min adjustable |

| X Axle Moving Range |

≥1300mm |

| Y Axle Moving Range |

≥760mm |

| Z Axle Moving Range |

≥250mm |

| A Axle Moving Range |

360° |

| Rated Air Pressure |

0.8MPa |

| Air Consumption |

1m3/h |

| Water Pressure |

0.2Mpa |

| Water Temperature |

10-20℃ |

| Cooling Water Consumption |

1000L/H |

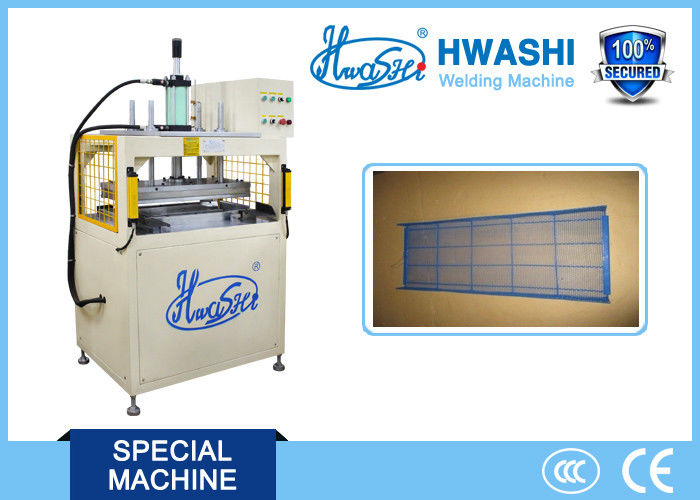

CNC Spot Welding Machine for Welding Tray Wire Mesh of Kitchen Rack and Flower Part

According to the specification provided by our customer, we adopt the design of single-electrode X, Y axis automatic mobile type welding machine which can be matched with different welding fixtures. The operator only needs to input the parameters like the coordinate data and welding current, then the machine will conduct automatic welding after start. Workers only need to put and take the work piece manually. This machine is of simple structure which will make the assembly very easy. It also can be matched with different welding equipment. The servo motor will drive the X and Y axis to run within the preset PLC programming. It can max store 5000 welding spots. This machine is suitable for batch welding of wire mesh. The MF DC pulsed power supply is of low cost and low consumption which can help reduce the impact to the power grid and ensure the stability of the welding spot.

According to your requirement, the maximum moving rang of X Axis of the automatic feeder is 550 mm, and the maximum moving rang of Y Axis is 400mm.

| NO. |

Item |

Parameters |

| 1 |

Input Voltage |

380V Three Phase |

| 2 |

Power Capacity |

90KVA |

| 3 |

Input Current |

200A |

| 4 |

Output Voltage |

DC11.5V |

| 5 |

Maximum Welding Current |

15000A |

| 6 |

Maximum Welding Model |

101 types |

| 7 |

Welding Position |

5000 points |

| 8 |

X Axis Effective Width |

550mm |

| 9 |

Y Axis Effective Width |

400mm |

| 10 |

Moving Speed of fixture feeder |

500mm/sec |

| 11 |

Welding Cylinder |

160x100mm |

Automatic Bending Machine for Wire Mesh

This special machine adopts gantry type steel frame structure and its upper and lower cutting mould is made of national standardized die steel. Use hydraulic system as the power and adjustable device for oil cylinder. The machine can effectively control the pressure stroke and adjust the bending angle.

Features:

Easy and convenient operation, use pedal switch to complete the bending work;

Adopt hydraulic system as the power , large bending pressure and stable performance;

Adopt the national standardized die steel which is wear-resisting and with long service life;

Adopt steel structure on the whole machine, no vibration, enough strength and stability ;

Easy and convenient adjustment of back gauge device

Quick adjustment of cutting edge gap

Counting device

Lighting function

| NO. |

Technical Specification |

Parameter |

| 1 |

Maximum Pressure |

10T |

| 2 |

Fast Forward Speed |

30mm/sec |

| 3 |

Working Speed |

10mm/sec |

| 4 |

Length of working Table |

900mm |

| 5 |

Width of Working Table |

600mm |

| 6 |

Distance between the guide stems |

900mm |

| 7 |

Throat depth |

200mm |

| 8 |

Maximum open height |

200mm |

| 9 |

Power of main motor |

7.5kw |

| 10 |

Overall dimensions |

1250x1500mm |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!